“A boat is a reflection of its owner.”

Making the sailboat to powerboat switch is fairly common, inevitable for some. Owners of now MV “Whirlaway” were coming from an absolute turn-key blue water sailing Bristol 47. If they were to take the powerboat plunge it would have to be a larger classic New England style trawler, but needed to go a bit faster. An Alden 50, which they felt the Ray Hunt designed hull could support more horsepower and thus gain considerable speed rather than just plowing more water, was their choice. Hunt had been famous for fast hulls dating back to the early 1960s, why not try a 1990s hull with larger engines……40% larger.

Along with what seemed all Departments involved in accessing & extracting the original motors, major works by JBY Mechanics & Fiberglass techs to engine beds, shaft logs, running gear/props, exhausts, ventilation, sound proofing, charging systems, etc. made this original 12 to 14 knot cruiser now effortlessly leap along above the water 20 to 24 knots. Vision confirmed.

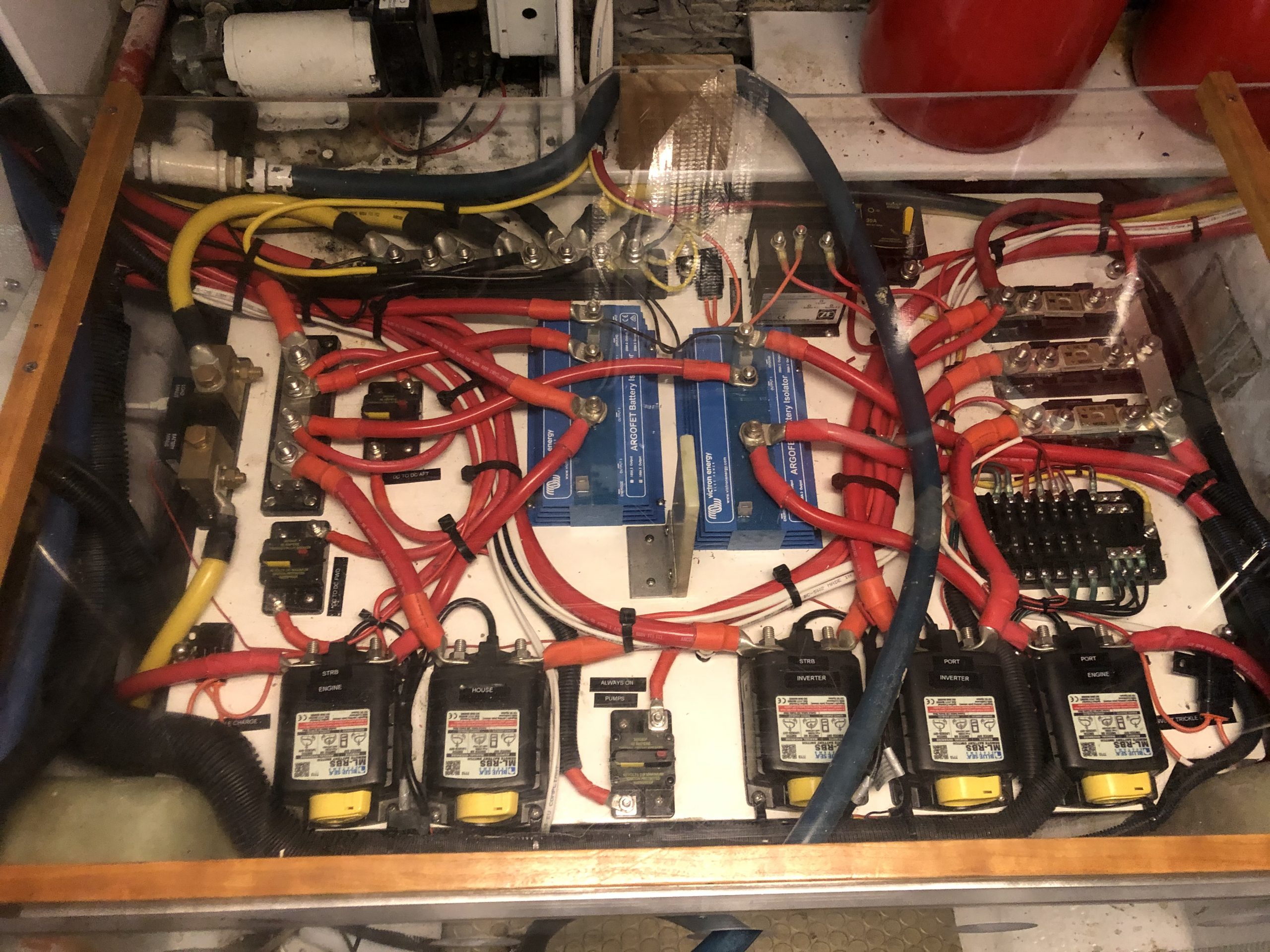

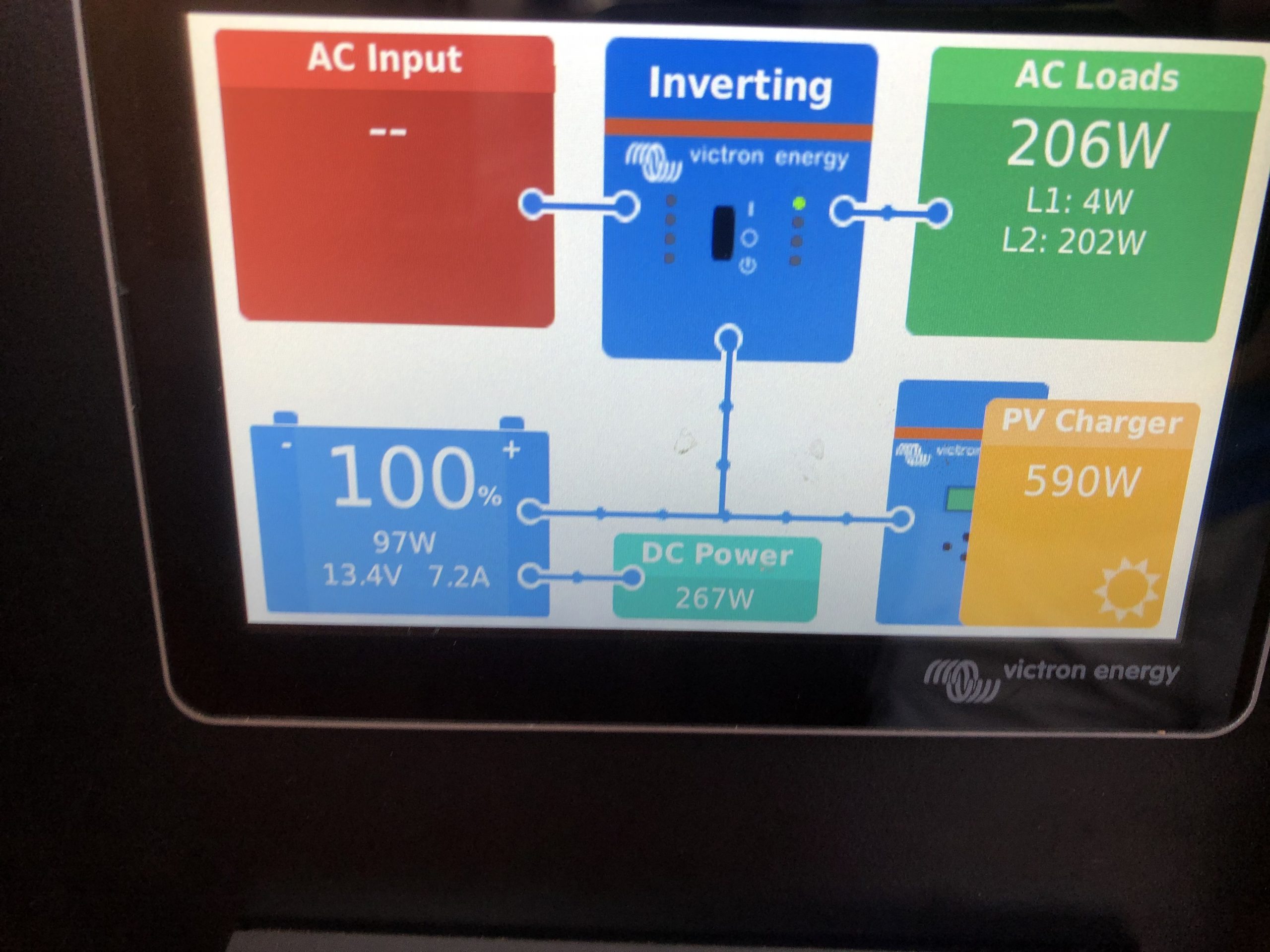

JBY Mechanics had plenty of other tasks to include installing completely new DC/AC wiring/inverting/solar/charging/monitoring systems designed and installed with strong emphasis on being completely independent of shore-power. New bow & stern thrusters. Normal routine maintenance schedules; details exhaustive.

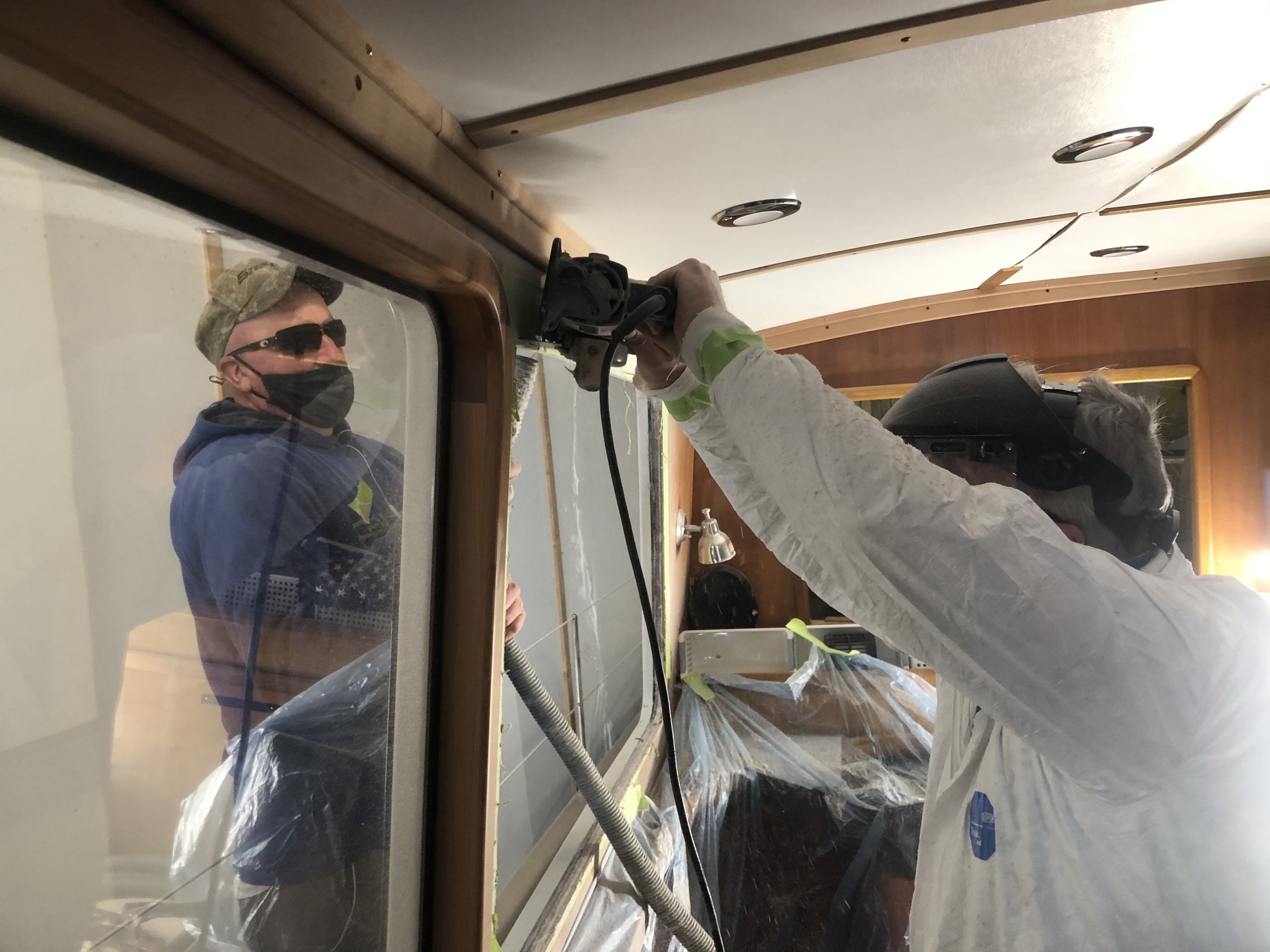

Not to be over shadowed, JBY Carpentry was tasked with…….well, changing the salon & galley layout with extensive custom cabinetry, modifying the forward cabins for more storage and modified/upgraded berths for this family’s expanding generations, new teak decking, new side windows, new headliner & lighting.

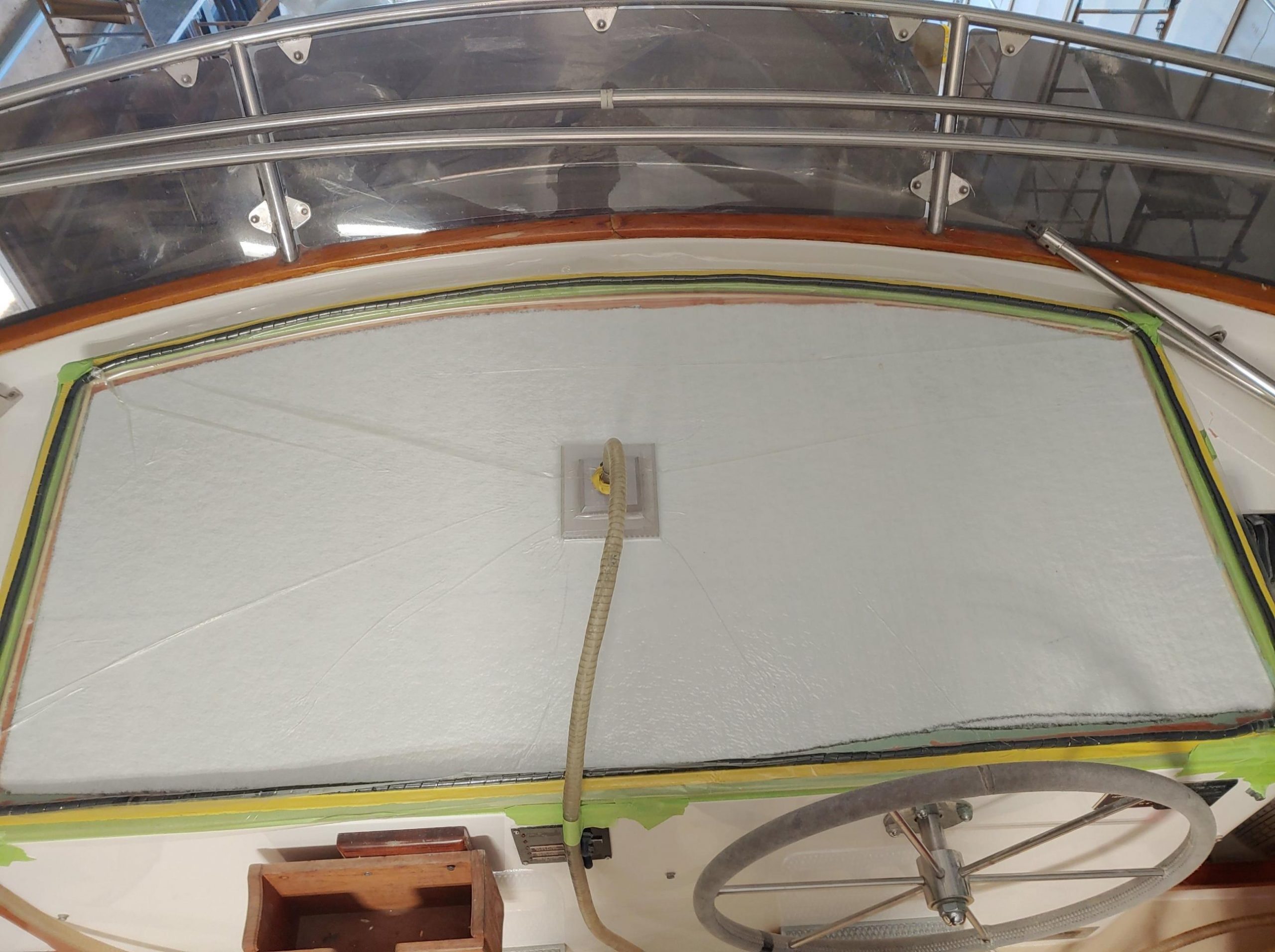

Other major works to include new custom carbon fiber hard-top with solar arrays, new windlass, new watermaker, new refrigeration, new electronics, new dinghy stowage, new mast layout and Awlgrip, and a “bit” of varnish inside & out.

Tackling one of our largest projects to date during the initial year of the Covid pandemic wasn’t ideal; but we’ve never been more proud of our staff and additionally would like to recognize our vast array of dependable suppliers & subcontractors that helped us thru.

Ray Hunt Design, Cummins Diesel, Ocean Planet Energy, Victron Energy, Moore Brothers Composites, Accutech Propellers, Soundown Corporation, Alumatech, Teak Decking Systems, Cay Electronics, Hinckley Cushions, Kinder Industries, New England Boatworks, Pompanette, The Metal Guy, Bolie Yacht Varnish, Imtra Marine Lighting, Side Power Thrusters, Maxwell Windlass, Spectra Watermakers, Sea-Frost Refrigeration.